What Is Decarboxylation?

Decarboxylation is the process of activating cannabinoids in hemp by converting their acidic forms into neutral, usable compounds. In raw hemp, CBD exists primarily as cannabidiolic acid (CBDA), which has different properties and is less widely used in finished products. When heat is applied in a controlled manner, the carboxyl group (-COOH) is removed from CBDA, transforming it into active CBD.

This transformation is essential for manufacturers because it ensures that the final extract delivers predictable, consistent results when used in oils, CBD capsules, topicals, or edibles. While decarboxylation can occur naturally over time through exposure to air and light, professional producers rely on controlled heating to achieve complete, efficient conversion. This precision enables brands to offer high-quality CBD products that meet industry standards for potency and consistency.

Why Decarboxylation Matters in Manufacturing

For CBD manufacturers, decarboxylation is not optional. It is a critical step that transforms raw hemp material into a reliable, market-ready ingredient. By converting CBDA into active CBD, producers ensure their extracts meet consumer expectations for effectiveness and consistency.

Proper decarboxylation also improves formulation flexibility. Active CBD is more readily incorporated into oils, capsules, topicals, and other delivery formats, supporting precise dosing and consistent quality across batches. This is especially important for brands focused on building trust through transparent labelling and dependable results.

Additionally, mastering decarboxylation is key to operational efficiency. Controlled heating allows for predictable processing times and yields, reduces waste, and supports scalable production. For any brand committed to delivering high-quality, compliant CBD products, understanding and optimising decarboxylation is essential.

Important Factors to Consider

Successful decarboxylation is more than simply applying heat to hemp. For manufacturers, getting the process right is essential to ensure product quality, potency, and consistency.

Temperature and time must be carefully balanced. If the temperature is too high or applied for too long, valuable cannabinoids and other beneficial compounds can degrade, reducing the quality of the final product. Conversely, if the temperature is too low or the time too short, decarboxylation may remain incomplete, leaving CBDA unconverted and lowering the product’s effectiveness.

Manufacturers aim for precise, consistent heating profiles that maximise CBD activation while preserving other plant compounds such as terpenes. Careful process control supports batch-to-batch consistency, regulatory compliance, and customer trust. This attention to detail is what distinguishes high-quality CBD production from less reliable methods.

Is CBD Decarbed Before or After Extraction?

Manufacturers can choose to perform decarboxylation either before or after extraction, with each approach offering specific advantages. Pre-decarboxylation is often preferred because it simplifies the extraction process and improves overall efficiency.

By applying heat to the hemp material before extraction, moisture is removed, which can speed up extraction times and improve process consistency. Acidic forms of cannabinoids, such as CBDA, are less soluble in certain solvents. Decarboxylating beforehand converts them into their neutral forms, making them more compatible with extraction methods such as supercritical CO₂ or hydrocarbon-based systems.

While post-extraction decarboxylation is also possible, it typically requires additional process steps and equipment to ensure uniform heating without degrading valuable compounds. Manufacturers often choose the pre-extraction method to streamline production and maintain high-quality yields.

Preparing Hemp Material for Decarboxylation

Effective decarboxylation starts with proper preparation of the hemp material. Manufacturers know that the quality of the starting material directly influences the consistency, potency, and overall quality of the final CBD product.

The first step is selecting high-quality hemp that meets testing and regulatory standards. Using well-cultivated, contaminant-free biomass ensures reliable cannabinoid content and reduces risks during processing. Next, the hemp is ground into smaller, uniform pieces to increase surface area. This promotes even heat distribution during decarboxylation, ensuring thorough conversion of CBDA into CBD.

Professional production also requires carefully controlled environmental conditions. Clean facilities, precise equipment calibration, and consistent batch records all support compliance with GMP standards and food-grade requirements. By preparing hemp material properly, manufacturers set the foundation for safe, effective, and high-quality CBD production.

The Different Methods of Decarboxylating Hemp

Professional CBD manufacturers use a range of decarboxylation methods to achieve consistent, high-quality results. Each method offers unique advantages, suited to different production scales, budgets, and product goals. Below are some of the most common techniques used in the industry.

Oven Decarboxylation

This method involves heating hemp buds or trim in an oven at controlled temperatures for a set duration. Typically, the material is heated at around 115°C (240°F) for 30 to 45 minutes. While simple and effective, professional operations rely on precision ovens with accurate temperature controls to avoid overheating or underheating, both of which can impact cannabinoid content and quality.

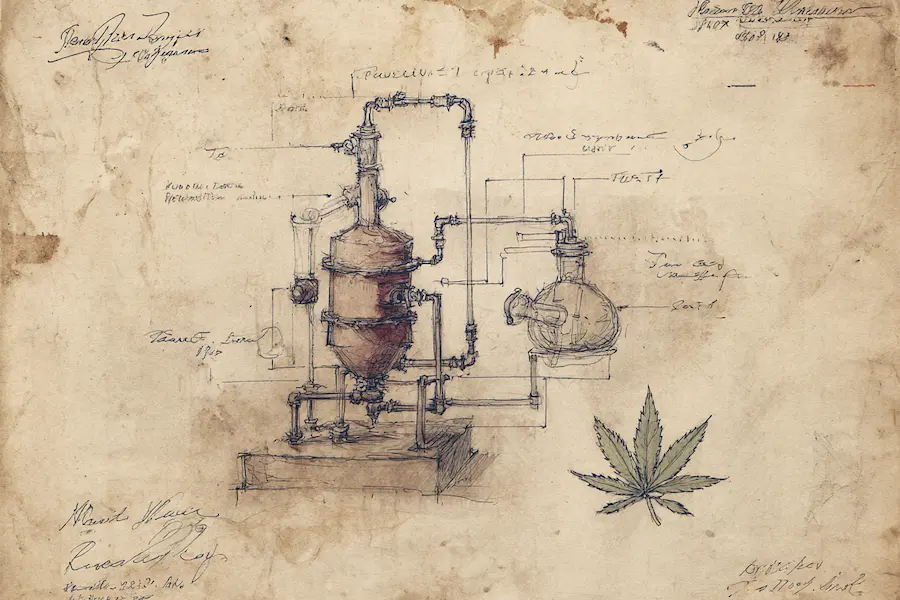

Closed-Loop Decarboxylation

Closed-loop systems allow manufacturers to carefully control temperature, pressure, and time throughout the decarboxylation process. This method improves consistency while minimising the loss of volatile compounds such as terpenes. By managing these variables precisely, producers can achieve reliable, repeatable results that meet strict quality standards.

Vacuum Decarboxylation

Vacuum ovens or sealed systems allow decarboxylation to occur at lower temperatures by reducing atmospheric pressure. This approach helps preserve sensitive compounds like terpenes and other volatiles that can degrade under higher heat. Manufacturers aiming to produce full-spectrum CBD products often prefer vacuum decarboxylation to retain a broader range of beneficial plant compounds.

Fluidised Bed Decarboxylation

This advanced method suspends hemp material in a stream of hot air, ensuring even heating throughout the batch. Fluidised bed technology delivers consistent activation of CBD and is particularly useful for large-scale operations that need efficient, uniform processing. It allows manufacturers to maintain quality while scaling production.

Decarboxylation Machines

Specialised decarboxylation machines are designed to manage key variables such as heat, time, and airflow automatically. These machines help standardise the process, reducing human error and supporting consistent batch quality. For companies seeking to scale production while maintaining high standards, investing in dedicated decarboxylation equipment offers clear advantages.

Infrared Decarboxylation

Infrared technology heats hemp material rapidly, offering faster processing times. This method can improve production efficiency, but it requires careful control to avoid overheating and degrading cannabinoids. Manufacturers adopting infrared systems prioritise precise monitoring to maintain product potency and quality.

Microwave-Assisted Decarboxylation

Some producers use microwave-assisted systems to speed up decarboxylation. These systems require specialised equipment to ensure even heating and effective conversion without damaging valuable compounds. Professional manufacturers rely on their expertise and strict quality controls to adapt microwave methods for consistent, high-quality production.

Regulatory and Quality Considerations

For CBD manufacturers, decarboxylation is not just a technical step but a critical part of maintaining regulatory compliance and consistent product quality. Proper decarboxylation ensures accurate cannabinoid profiles, which support precise labelling and help meet local regulations on content and safety.

Manufacturers must also maintain thorough documentation of their decarboxylation processes, including temperature controls, batch records, and equipment calibration logs. These records support compliance with Good Manufacturing Practice (GMP) standards and help demonstrate quality assurance to partners and regulators.

Additionally, food-grade and pharmaceutical-grade production environments require strict hygiene and contamination control. This includes validated equipment, trained staff, and routine testing for cannabinoid content, residual solvents, heavy metals, and microbiological safety. By integrating these quality and compliance measures into the decarboxylation stage, manufacturers strengthen their brand reputation and ensure their products are safe, reliable, and market-ready.

Summary

Decarboxylation is a vital process in CBD manufacturing that transforms the acidic forms of cannabinoids into their active states. By applying controlled heat, manufacturers ensure consistent, effective CBD content suitable for CBD oils, capsules, topicals, and other formulations.

Successful decarboxylation relies on precise temperature and time management, careful preparation of hemp material, and selection of the right method to preserve cannabinoids and other valuable compounds. Professional producers choose from techniques such as oven, vacuum, closed-loop, and fluidised bed decarboxylation, each with its own advantages for scale and product goals.

Equally important is the commitment to regulatory compliance and quality control. Detailed documentation, GMP standards, and routine testing all support the production of safe, reliable CBD products that meet customer expectations and legal requirements. For brands looking to stand out in a competitive market, mastering decarboxylation is essential to delivering high-quality, trusted CBD formulations.